Dear Itasca team,

I am simulating an axial tension test on a shell specimen. In the model, the two end segments of the shell are connected to deformable blocks via rigid connections (constrained in all translational degrees of freedom). A tensile velocity is applied to these blocks.

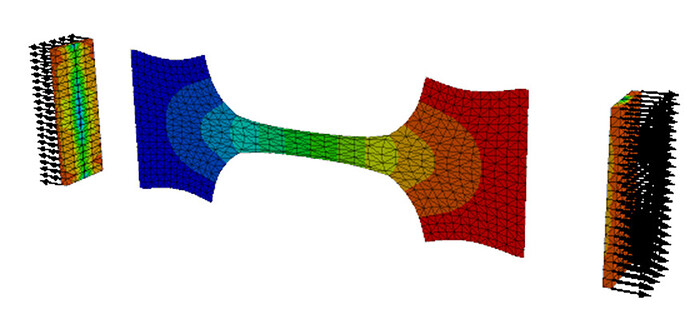

However, during the simulation, significant gaps appear between the shell ends and the blocks, despite the shell being stretched under the applied load (the deformed factor of block and that of shell element in the plot view were set the same). Given the rigid connection setup, such separation should not occur at the interface. Please take a look at the images below for more information.

Could you please help me understand the possible causes of this issue and suggest how to prevent it?

Thank you very much for your support.