Hello,

I have been running triaxial testing simulations on a rock specimen in PFC. Initially, everything was working fine — the test ran quasi-statically (I ensured this by lowering the strain rate value), and the stress–strain curves and other history plots were generated correctly.

However, when I started running multiple tests at the same time, I opened two PFC windows and ran two models simultaneously. After that, I began experiencing problems:

- Histories are not being recorded or plotted.

- Stress–strain curves and related history functions give either no output or nonsensical results.

Even when I try to re-run the same model setup that worked before, the histories no longer track properly.

Could this be caused by running multiple PFC sessions in parallel, or is there another reason why histories and plots would suddenly stop working? Has anyone experienced this issue before, and what would be the best way to resolve it?

Thank you in advance for your help.

Best regards,

Alaa

Hello @AlaaAbdallah

I’ve never heard of running parallel instances of PFC interfering with each other. It would be highly unlikely.

I agree with Derrick. I do this ALL THE TIME with PFC. We have been having some issues when running PFC on high-powered PCs that are in a room that is not well cooled.

Dear @dblanksma @dpotyondy

Thank you so much.

I am currently running the uniaxial compression test in parallel with a 10 MPa triaxial compression test. The UCS seems to be working properly, but the 10 MPa triaxial test does not produce correct results.

The UCS test has been running for more than five days and is still ongoing. Could the extended runtime of the UCS be affecting the 10 MPa test? I have also been running simulations continuously in PFC for about a month—might this be related to the problem? I have a model of 10000 particles to represent a rock specimen.

I would greatly appreciate any advice you can share.

Best regards,

Alaa

I am mostly speculating here - the only affect the two models will have on each other is increasing the amount of simulation time. However, it your models are appr. 10k balls, I doubt there will be much of an affect, since that is considered to be a relatively small model.

I would check the UCS test solve criteria - has the model reached failure, does it continue in the post-peak, what are the conditions for terminating the test if it has reached post-peak, or is the test still showing an elastic response and needs more computation time (5 days, one would assume a 10k ball model would easily have completed).

I cannot comment on the triaxial test since I have no metric for “does not produce correct results”. I would suggest sending a more detailed description of the problem and the model files to pfcsupport@oneitasca.com

Hello @dblanksma ,

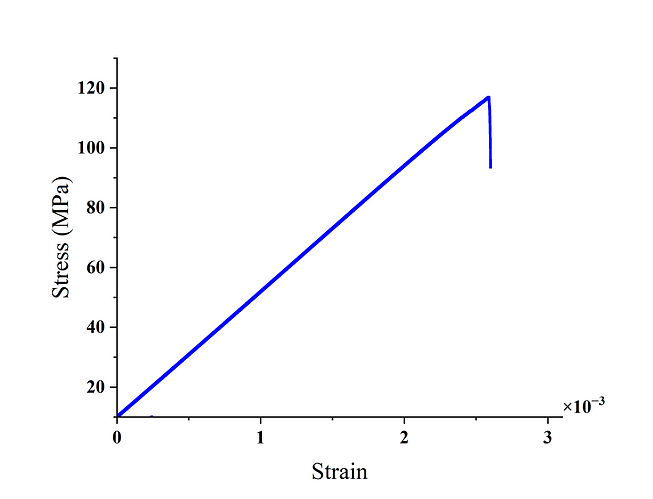

The UCS test has been completed successfully, and I obtained a brittle failure response, which appears to be correct. (Please find the attached image.) The load was applied until 80% of the maximum stress was reached.

I no longer have any issues with the UCS test. However, I am still encountering problems with the triaxial tests when applying a confining pressure of 10 MPa or higher. The test seems to work properly at 1 MPa, but not at higher pressures.

I also tried using the original model from the Material Modeling Support Package (which has fewer particles) under 10 MPa confinement, and I observed the same issue as in my current model.

I will contact pfcsupport@oneitasca.com and hope to resolve this issue as soon as possible.

Best regards,

Alaa